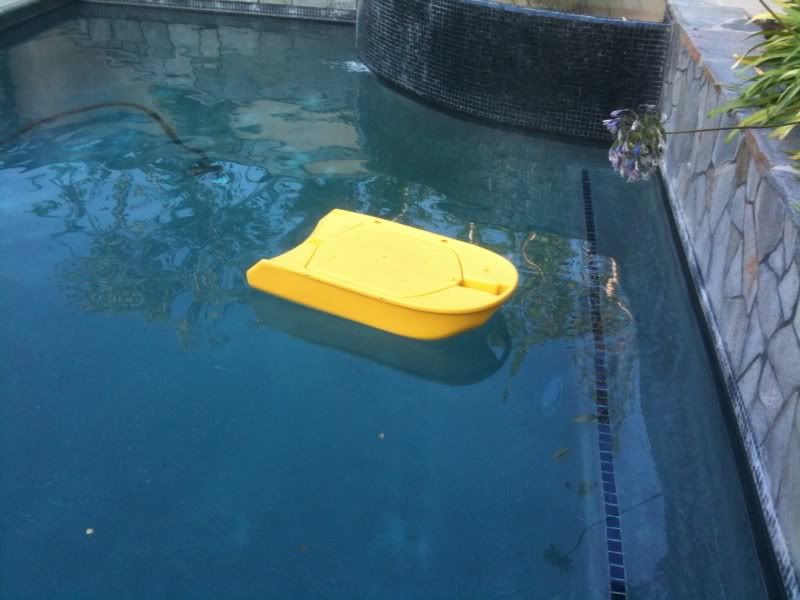

following is a summary in photos of my float from the beginning to the present:

My nanny had to go to China to care for her dad who was ill which forced me to stay at home with my kids so I started getting creative....

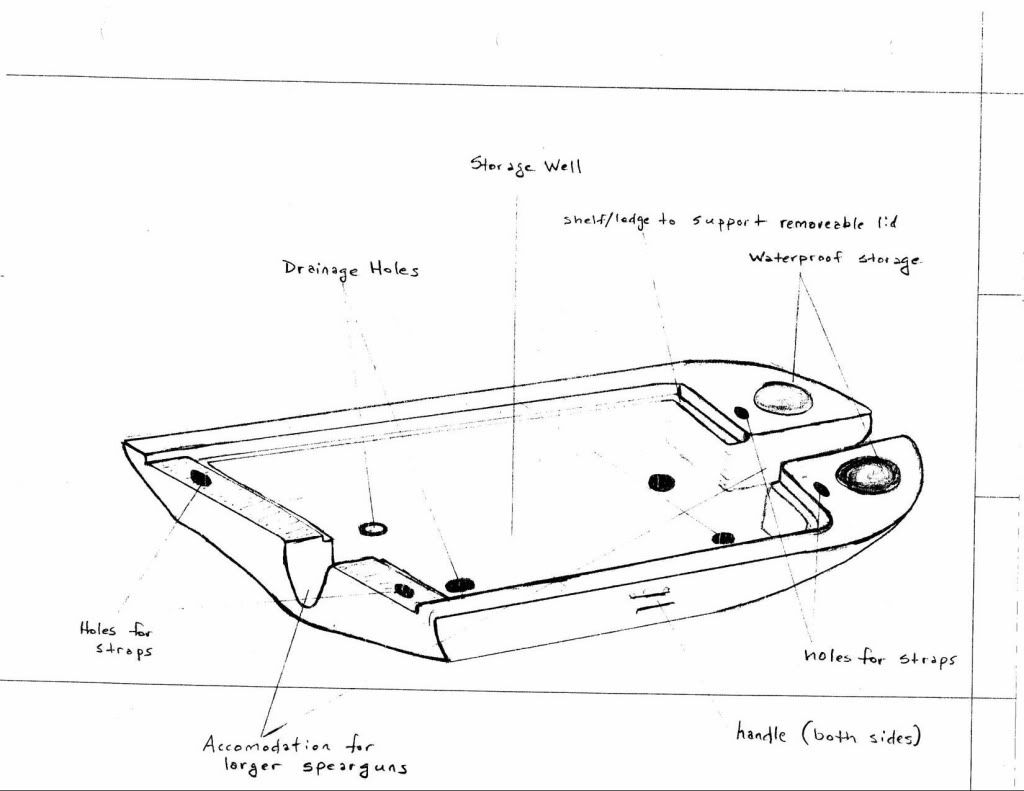

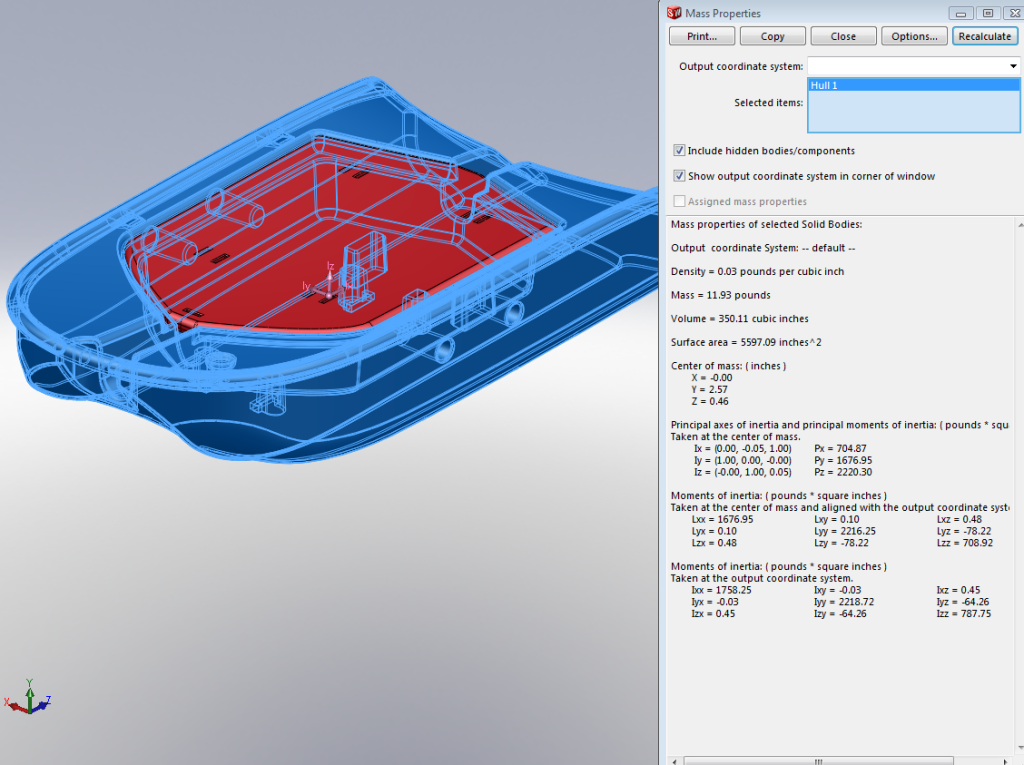

I contacted some rotational molding companies and they introduced me to an excellent engineer - Guy Cazort, he helped me put my design into 3D CAD.......

Then began the physical process of making a wooden copy......

Then began the cast aluminum mold....

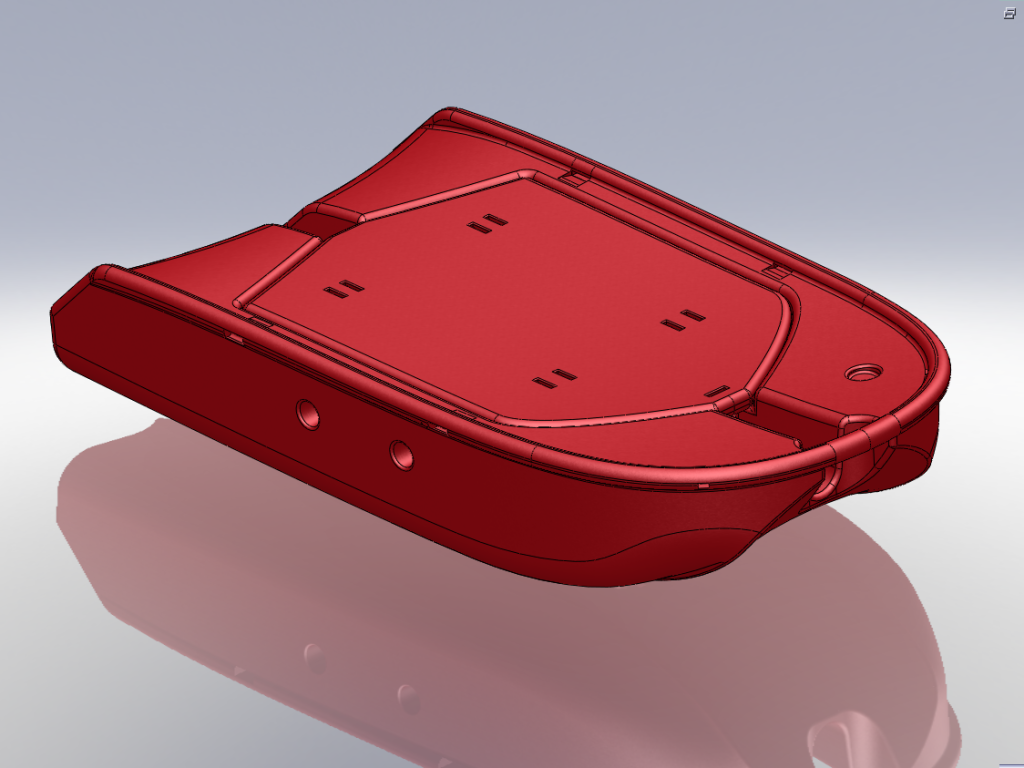

I then began negotiating with several rotational molders - prices varied quite a bit (from about $3 per pound to 6 per pound) Rotonics made my first test parts...

Currently the mold is receiving some modifications and I am working on finishing details - e.g. straps, hardware, attachment points, etc. It will be ready very soon.